Custom Prototyping

Quality of Precisions, Reliable Processes, Industry Experiences

100$ /

per hour

Insured, leather interior, rain sensor, air conditioning.

$3.00 /

per hour

FDM 3D Printing with thermal plastic or composite polymer

About us

We make sure that your every job is successful

We guarantee job success through a perfect blend of cutting-edge technology, expert craftsmanship, and unwavering dedication to precision.

Our Services

We offer preproduction evaluation, product design inputs, productions planning

FDM 3D Printing

FDM’s additive nature and soluble support material simplify the creation of parts with complex geometries and internal cavities. FDM technology is clean and office-friendly, thanks to production grade materials that are mechanically and environmentally stable. FDM thermoplastics also deliver the necessary properties for applications that demand precise tolerances, durability, and stability in different environments. They include many of the same thermoplastics used in traditional manufacturing processes like injection molding.

CJP Full Color Modeling

ColorJet Printing (CJP) is an additive manufacturing technology with two main components: core material and binder. The core material is spread in thin layers over the build platform with a roller. After each layer is spread, color binder is selectively jetted from inkjet print heads, causing the core to solidify. The build platform lowers to allow every subsequent layer to be spread and printed, resulting in a full-color three-dimensional model.

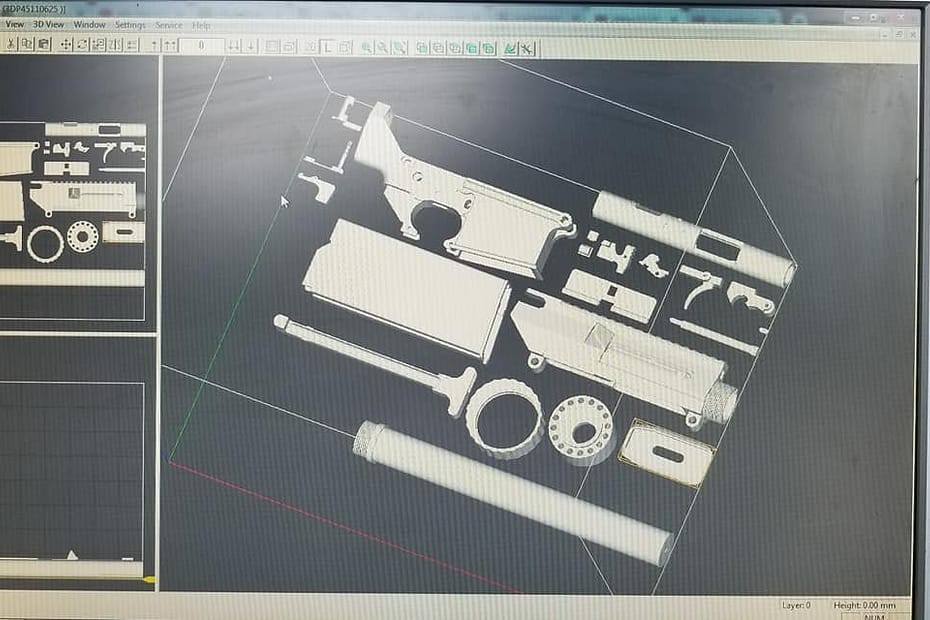

CAD Computer Aided Design

CAD stands for Computer-Aided Design. It is a technology that involves the use of computer systems to create, modify, analyze, or optimize designs for various purposes. CAD software is commonly used in engineering, architecture, product design, and other fields to facilitate the design and drafting of objects, buildings, or systems. CAD allows designers to create accurate and detailed representations of their ideas, making it easier to visualize, analyze, and share designs before they are physically implemented.

CAM Computer Aided Manufacturing

CAM stands for Computer-Aided Manufacturing. It is a technology that uses computer software and machinery to automate and control manufacturing processes. CAM software is employed to generate instructions for machines and tools in the production of physical objects. The goal is to streamline and optimize the manufacturing process by automating tasks such as cutting, milling, and other machining operations.

In the context of the original statement, the progression from CAD to CAM suggests a seamless transition from the design phase (Computer-Aided Design) to the manufacturing phase, where the CAM software plays a crucial role in converting the design data into instructions for the machines that will produce the actual physical components.

NDT product Analysis

NDT stands for Non-Destructive Testing. It is a set of techniques used to evaluate the properties of a material, component, or system without causing any damage to it. NDT is commonly employed in industries such as manufacturing, construction, and maintenance to ensure the integrity and quality of materials and structures. The primary objective of NDT is to detect flaws, defects, or irregularities in a material or structure without causing any harm, allowing for preventive measures and quality control.

Various methods are used in non-destructive testing, including ultrasonic testing, radiographic testing, magnetic particle testing, liquid penetrant testing, eddy current testing, and visual inspection, among others. Each method has its specific applications and is chosen based on the material, the type of defect being sought, and the requirements of the testing procedure.

Why Choose Us

Explore our first class manufacturing methods

Rapid prototyping and CNC (Computer Numerical Control) machining are complementary processes often used in conjunction within the product development lifecycle. While rapid prototyping focuses on quickly creating physical prototypes for design validation and iteration, CNC machining is employed for the production of functional, end-use parts with higher precision and material variety. Here’s how these processes can work together:

Rapid Prototyping:

- Design Concept: The product design process begins with creating a 3D model using CAD software.

- Rapid Prototyping: The initial design is translated into a physical prototype using rapid prototyping techniques such as 3D printing or other additive manufacturing methods.

- Quick Iteration: Prototypes are evaluated, and design iterations are made swiftly based on the feedback. Rapid prototyping allows for a quick and cost-effective exploration of design variations.

CNC Machining:

- Final Design: Once a design is finalized through rapid prototyping, a more detailed and refined version is developed.

- CNC Programming: The finalized design is translated into CNC machine instructions using CAM (Computer-Aided Manufacturing) software.

- Material Selection: CNC machining can work with a wide range of materials, including metals, plastics, and composites, providing flexibility in material selection based on the application.

- Precision Machining: CNC machines use subtractive manufacturing processes to precisely remove material from a solid block or sheet, creating the final part.

Integration:

- Hybrid Approaches: Some manufacturing processes combine rapid prototyping and CNC machining in a hybrid approach. For example, a 3D-printed part might undergo CNC machining for additional precision or to achieve specific surface finishes.

- Transition to Production: After successful prototyping and validation, the final design can be scaled up for production using CNC machining or other mass production methods.

By integrating rapid prototyping and CNC machining, manufacturers and designers can benefit from the strengths of each approach. Rapid prototyping allows for quick design iteration and validation, while CNC machining provides the precision and material options needed for producing functional, end-use parts. This collaborative use of technologies helps streamline the product development process from initial concepts to production.

1.

Experienced Engineering

2.

Fixable Price

3.

Fast Product Delivery Service

4.

Professional Customer Care

Working with Volker Technology was a game-changer for our project. Their team’s attention to detail and expertise in prototyping made the entire process seamless. The prototypes they delivered exceeded our expectations, and the speed at which they turned our concepts into tangible models was truly impressive. Highly recommend their services!

James Oliver

Our experience with Volker was nothing short of fantastic. Their engineers demonstrated a deep understanding of our design requirements and provided innovative solutions that greatly enhanced the final prototype. The precision and quality of their work were remarkable. Collaborative, professional, and dedicated to delivering excellence

A+

Rosalee Melvin

We engaged Volker Tech for a challenging engineering project, and the results were outstanding. Their team’s expertise and attention to detail were evident in every aspect of the prototyping process. They not only met but exceeded our expectations. If you’re looking for a prototyping partner with technical prowess and a commitment to excellence, look no further.